Introduction

The construction industry is facing growing challenges in terms of efficiency and sustainability. At Hermosillo, these challenges drive us to continuously innovate and adopt technologies that reflect our integrated and responsible approach to building.

A clear example is one of our projects currently under development: a 25-story building with four basement levels, where we’ve implemented Placing Boom technology. This remotely controlled concrete-pouring arm enables precise, safe pouring, optimizing operations on vertical construction sites and supporting Lean Construction standards.

Its implementation is part of a strategy guided by Lean Construction, sustainability, and a solid risk-management framework. Furthermore, this project—which aspires to LEED certification—stands out for its environmental initiative: the reuse of leftover concrete to produce concrete blocks. This comprehensive solution reinforces our commitment to building efficiently, innovatively, and responsibly through Lean Construction, Sustainability principles, and continuous improvement practices that support quality construction and stakeholder satisfaction.

Alignment with Hermosillo’s Sustainability Strategy and Lean Construction Methodology

One of the main drivers behind adopting vanguard technologies, such as Placing Boom, is our Sustainability Strategy, which is structured around five pillars: Business Ethics, Holistic Employee Development, Environmental Action, Innovation and Technology, and Community Development.

This technology aligns directly with two of these pillars—Innovation and Technology, and Environmental Action—by improving efficiency, reducing risks on the construction site, and promoting environmentally responsible practices that align with the values of Lean Construction.

Our Lean Construction methodology further complements this approach, serving as a constant engine for continuous improvement, cost control, and cost saving throughout the construction site. This vanguard technology directly supports Lean principles by optimizing resources, time, and processes; maximizing material use—such as reusing leftover concrete—and encouraging team collaboration, standard work, and on-site problem-solving.

Additionally, its use enhances our risk and process management system, enabling a more controlled, safer, and predictable execution on the construction site. It reduces workers’ exposure at heights, improves workflow, and eliminates downtime related to moving heavy machinery, all while promoting Lean Construction efficiency, waste reduction, and continuous improvement.

By following Lean Construction practices, our teams achieve higher project efficiency, better resource utilization, and more predictable outcomes, which drive stakeholder satisfaction and ensure quality construction standards across every construction site we operate.

Technology and Efficiency in Vertical Construction

The Placing Boom system consists of a concrete placing arm installed at height, connected to a stationary pump at ground level through a network of pipes anchored to the building’s structure. As the building’s floor construction rises, the system adjusts accordingly, delivering concrete precisely where it’s needed—without interruptions across the construction site.

This mechanism combines:

1. Precision

2. Efficiency

3. Continuity

4. Safety

The articulated arm, operated remotely, directs concrete precisely to the desired area, even in hard-to-reach places. This solution has enabled us to expedite pouring processes while enhancing control, coordination, and minimizing operational disruptions.

By implementing Lean Construction practices and Lean principles within every stage of the construction site, our team continues to focus on continuous improvement, resource efficiency, waste reduction, and cost savings.

This approach reflects the Lean Construction mindset, which promotes standard work processes and consistent results across every construction site, ensuring efficiency, safety, and high-quality construction outcomes for our clients and stakeholders.

Concrete Blocks: Revaluing What Was Once Waste

Beyond its technical benefits, the use of Placing Boom also led to an environmentally friendly and innovative solution aligned with the project’s LEED waste-management plan and Sustainable and Lean Construction mindset.

Thanks to the improved control provided by this technology, our team identified and managed more efficiently the moments when concrete waste is typically generated during pouring on the construction site:

- When loading the pump.

- When lubricating the pipeline before pouring.

- When purging the pipeline after pouring.

Of these three moments, two can be fully utilized. Instead of throwing away the leftover concrete from lubrication and purging, the team started reusing it. They manufacture concrete blocks on-site.

This proactive and sustainable practice, rooted in Lean Construction, continuous improvement, and Lean principles, has helped reduce logistics, storage, and recycling costs, while also decreasing the amount of solid waste sent to authorized landfills.

Currently, more than 25 pours are performed each month on this construction site, producing two blocks per pour, for a total of over 140 blocks manufactured to date (as of September 2025).

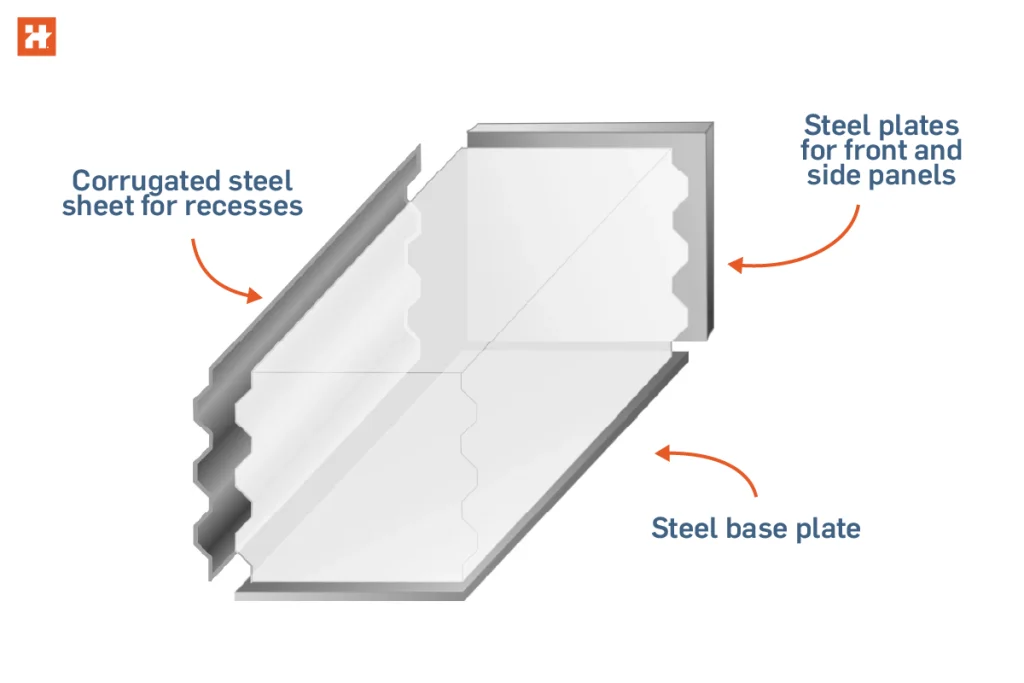

The molds are built using leftover steel materials from the project, with corrugated sheet metal used for the side interlocks and plates for the front, back, and base. The standard dimensions of each block are 2 x 2 x 6 feet.

The result is a robust, versatile block suitable for multiple applications, including:

- Retaining walls with slopes up to 45°.

- Concrete counterweights for tilt-up wall leveling.

- Counterweights for stabilizing metal or temporary structures.

- Confinement elements in work zones.

Although not all blocks are being used in the same construction site, they are safely stored for future projects or potential donations to social or community projects, extending the positive impact beyond a single Lean Construction initiative.

This reflects Hermosillo’s philosophy of sustainability and Lean Construction, which optimizes materials, enhances project efficiency, and promotes continuous improvement in the construction industry, thereby contributing to long-term sustainability and stakeholder satisfaction.

Conclusion

The use of Placing Boom technology is a clear example of how innovation, guided by Lean Construction philosophy and Lean principles, can translate into more efficient, cost-effective, and sustainable projects across the construction industry.

Thanks to these technological tools and the implementation of Lean Construction practices, we achieve productive work that reduces waste, improves precision, and enhances project efficiency throughout the entire planning and execution process.

At Hermosillo, every technical advancement is driven by purpose and a commitment to continuous improvement and Lean Construction excellence, delivering quality construction, minimizing environmental impact, achieving cost savings, and strengthening stakeholder satisfaction through waste-free construction, waste reduction, and sustainable practices that enhance the construction site experience and long-term performance.