If there’s room for improvement, you must be aware of it. At least, that’s our ethos. To be meticulous in your project’s development, applying techniques such as Value Engineering (VE) is crucial because it guarantees the best version of the project to your client and users. For this reason, we want to share our unique VE vision with you. In this post, we will offer a simple 160-character definition that tackles the essential aspects of VE. If you want to dig deeper, you will find a thorough concept explanation plus real-life examples.

The 160-character definition of Value Engineering

Value Engineering is a methodology for identifying opportunities to increase a project’s value by maximizing functionality and performance at an optimal cost.

Breaking down the concept of Value Engineering

It’s simple: VE is a systematic way of improving a project. Nevertheless, two essential ideas and specifications differentiate VE from any other problem-solving method: methodology and value. To better understand the concept, we will break it down into these two ideas.

History and Evolution of Value Engineering

Value Engineering originated during World War II and was developed by General Electric to respond to the scarcity of materials and resources. Lawrence Miles, an engineer at GE, designed this approach as a systematic way to analyze projects to improve functionality without increasing costs. Since then, VE has evolved and expanded into various sectors, such as construction, manufacturing, and engineering, gaining worldwide relevance. Today, VE is a key tool in optimizing complex projects, enabling multidisciplinary teams to identify and maximize improvement opportunities to offer the best balance between cost and performance.

How is Value Engineering a methodology?

Value engineering is a systematic approach that pursues a Job Plan. Following a method allows the interdisciplinary team to produce consistent and better results in any discipline or trade of a project. Whether the challenge is to substitute one material, equipment, and/or system for another or to limit environmental impact, applying the VE method helps identify unnecessary costs and offers a different yet precise solution tailored to each situation.

Said Job Plan follows these phases:

- Information phase: The team seeks relevant information about the project, including owners’ objectives (basis of design), key criteria, and definition of value.

- Function analysis: The goal is to identify and understand the project’s needs, product, or service (what does it do, what must it do).

- Creative phase: This is the brainstorming phase. Here, the interdisciplinary team studies the information gathered in Phase 1 and focuses on defining possible VE ideas that can bring tangible benefits (based on Phase 2 functions) to the project.

- Evaluation phase: The team evaluates each idea produced during the brainstorming session; some are kept and others discarded.

- Development phase: The team develops the kept VE ideas into workable and technically feasible proposals, each one accompanied by a list of pros and cons, along with cost comparisons.

- Presentation phase: The team makes a formal written presentation of their findings and an oral presentation to clients, users, and designers. In this final stage, the client can determine which value proposals will be incorporated into the project.

You can use this systematic process in any phase of the project’s life cycle, whether pre-construction, design, or construction. However, VE proposals done during the pre-construction phase are the most cost-effective, as they allow, for instance, early consideration of alternative materials, which can significantly impact cost and performance.

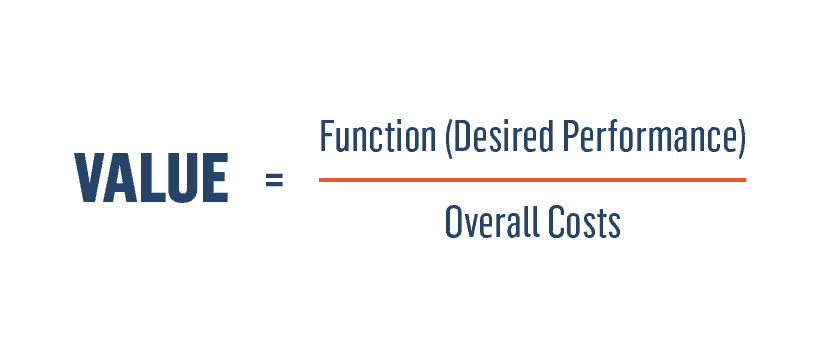

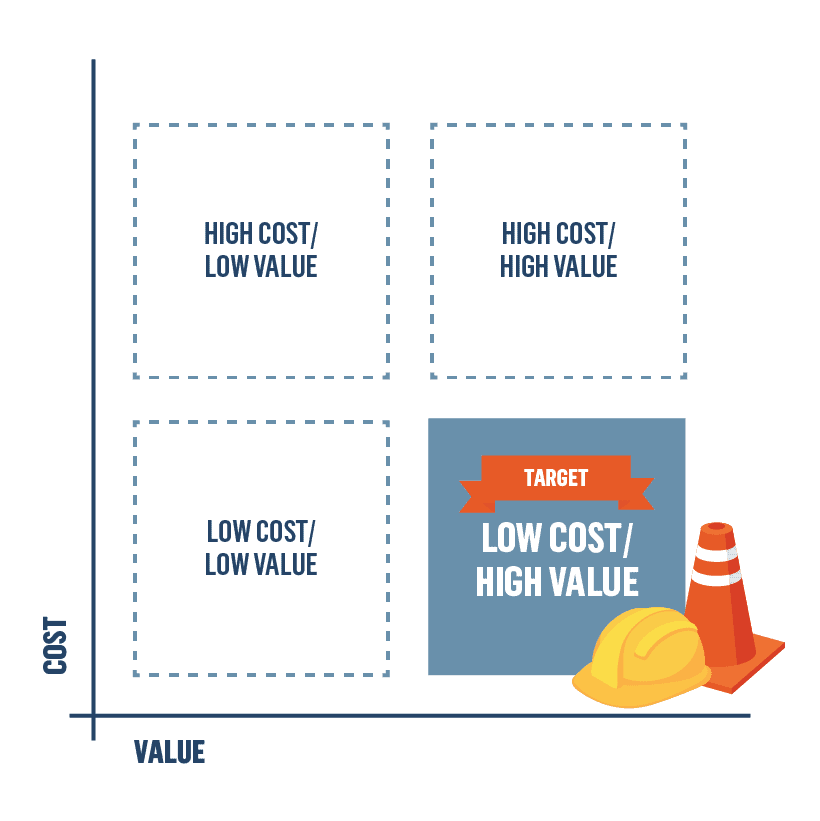

How does Value Engineering provide Value?

As stated in the 160-concept, Value Engineering aims to increase the project’s value by detecting opportunities for improvement. Value is linked to its functionality in the first place and costs in the second. Therefore, VE should NOT be mistaken as a technique to avoid being over budget or solely to reduce costs. The true goal is to maximize function and performance while seeking cost-effective solutions. It can be summarized in the succeeding formula:

To determine the function (see phase 2 of the methodology), you need to ask questions like the following:

- How long will those materials or equipment last? What is their performance? Can it be improved?

- What type of maintenance will they need in the future?

- Will they work more efficiently and cost less to operate?

- The best place to start is to ask yourself: what is/are the most important part(s) of the project and what performance do you want the project to achieve?

- In the end, functionality is determined by the owner’s and user’s goals.

Value Engineering Examples

The following example will briefly describe the VE process in the pre-construction phase before delivering a cost strategy to the client.

- Step 1. The interdisciplinary team reviewed the project’s information, RFP, and conceptual blueprints to fabricate an accurate cost strategy for the client.

- Step 2. When working on the proposal, the team and the electrical expert identified that changing the location of some transformers would result in savings in low-voltage feeders, given the distribution that the client required.

- Step 3. The team evaluated and developed a solution that didn’t compromise the facility’s quality and operativity.

- Step 4. The team presented this solution as an alternative and explained the advantages to the client.

- Step 5. After the meeting, the client validated the solution with its technical team and accepted the proposal. This VE solution was cost-effective and improved the facility’s functionality.

You can also check out this case study of a bridge construction project in which VE works saved the builder company approximately $43,000,000 and 12 months in total. This saving provided the builder company with a 6% financial savings and a 17% worktime reduction.

Value Engineering and Sustainability

Value Engineering focuses on reducing costs and improving long-term performance and efficiency, making it an essential tool for developing sustainable projects. By applying VE, teams can identify solutions that reduce energy consumption, optimize the use of recyclable materials, and minimize the project’s environmental impact. In a context where sustainability is increasingly essential, VE helps balance economic and environmental needs, delivering added value to clients and the planet. Implementing VE during the pre-construction phase can make a significant difference by ensuring a more efficient and sustainable project.

Selection Criteria for Critical Functions

In the analysis phase of value engineering, it is essential to identify the functions that have the most significant impact on the construction project. This includes a thorough examination of both the project requirements and client expectations to ensure that the selected functions contribute to project progress, generate substantial savings, and optimize the project’s functionality.

During this phase, the team can benchmark essential functions and consider design alternatives or acceptable substitutes that maintain high quality while reducing operating costs. Correctly selecting these functions ensures a systematic approach that maximizes project profitability and optimizes its life cycle. In this process, the project team explores various options through brainstorming, identifying critical areas for improvement, and opportunities to implement more efficient solutions.

Interdisciplinary Participation

The value engineering methodology is based on collaboration between disciplines, ensuring that a comprehensive approach supports each decision. An interdisciplinary team, including engineers, architects, designers, and cost specialists, ensures that all areas of the construction project are considered. This participation ensures that technical aspects and production costs, operating costs, and maintenance throughout the project’s life are addressed.

By working as a team, specialists can analyze alternatives that optimize the project’s functionality while minimizing costs and improving delivery times. This team approach fosters a constant exchange of ideas and allows for a better understanding of the concept. It results in more innovative and efficient solutions. Decision-making based on multiple perspectives ensures that the substantial improvements identified are feasible and beneficial in terms of cost optimization and risk reduction.

Impact on Sustainability

Value engineering plays a crucial role in improving the sustainability of projects. Through a systematic analysis of functions, opportunities can be identified to reduce energy consumption, use more sustainable raw materials, or implement technologies that minimize environmental impact. This approach allows for meeting the client’s expectations and aligning with international sustainability standards.

In practice, this may include evaluating design options that improve the building’s energy efficiency or integrating renewable energy sources that reduce long-term maintenance costs. Value engineering promotes sustainable and cost-effective design, ensuring the proposed solutions contribute to a lower environmental impact and better project performance. The result is a significant improvement in the quality of the project, both in terms of its functionality and sustainability throughout its life cycle.

Wrapping Up

Value Engineering is about developing ideas that generate value while systematically optimizing performance and costs. Remember, what sets it apart is that its central goal is enhancing the project’s functionality.

This practice is fundamental to any contractor who strives for continuous improvement. It’s a way of ensuring you are efficient in every step of the project’s lifecycle. As a result, contractors, clients, and users will be positive that the facility built is the best version possible.

For this reason, the VE process is part of our DNA. We are committed to delivering the highest-quality projects to our clients and partners. This method adds to our internal watermark: Forward Thinking, a framework we created as an internal guideline that allows us to keep our promises to you on budget, time, and quality.