We showcase our culture in every project we work on. Over the years, we have learned that LEAN Construction is not something you perform from project to project, but something you integrate into your company’s DNA. That is the difference between our first work and our last; we have turned ourselves into a LEAN Construction General Contractor, not just a practitioner.

As a result, we have managed to deliver projects on time. As Cesar Váldez, LEAN Construction Manager and Head of Mexico’s Chapter of LEAN CONSTRUCTION Institute said, we control the project, not the other way around.

We have learned that planning, in times of pandemic, is even more crucial. COVID-19 hit the construction industry hard, but with ongoing projects, deadlines, and many people involved, we had to keep working. In this situation of crisis, our hard work and LEAN Construction culture paid off. We managed to get through this circumstance giving solid results because of the way we work.

So we want to share that with you. In this post, we will go through our LEAN approach in one of our projects: Flex-N-Gate.

Related: Breaking down the concept of LEAN Construction

The Project

The project consisted of a 7,500 m2 expansion of an already-functioning facility. It included the construction of a concrete pad for materials storage, restrooms, a chemical room, and a parking lot.

LEAN Construction Tools

The goal was to keep everything on schedule and execute the project without stopping our Customers´ production. We used a hybrid of physical and virtual tools and made some adjustments to our frameworks to keep up with security guidelines.

- First, we implemented an Open Big Room. It worked phenomenally, mainly due to a very well-committed team. It was also a reminder of one cardinal LEAN Construction rule: let’s focus on humans, not on tools.

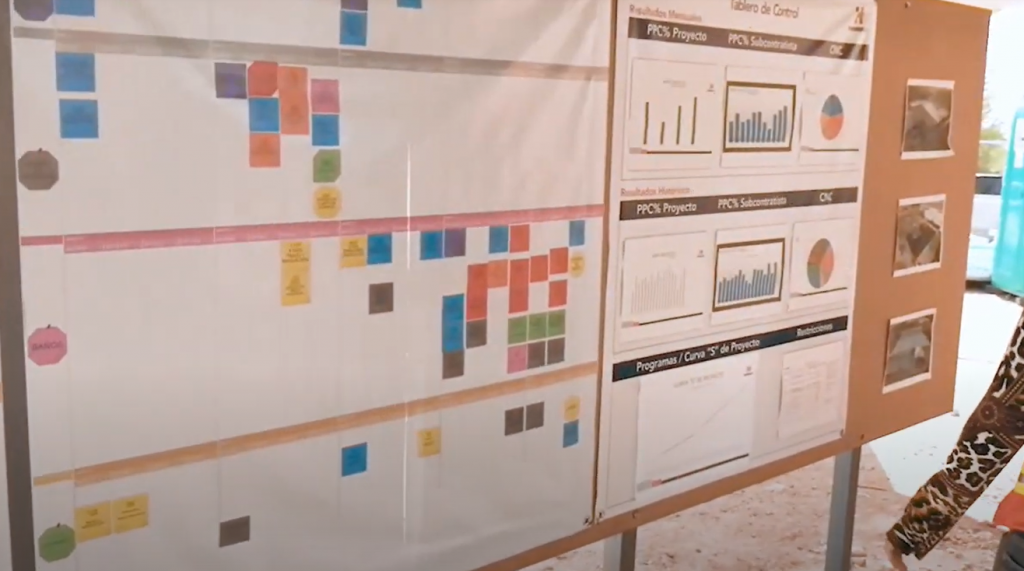

- We also had our Six Week Look-Ahead, which detailed the upcoming activities for the next six weeks.

- The Storm Board had the master plan, a very intuitive system that includes performance indicators. It helps us visualize our goal completion and team performance.

- Lastly, we implemented the Daily Huddle.

- We reviewed weekly activities. The goal was to identify what caused delays and non-compliance and learn from it.

- We made a weekly plan along with subcontractors and residents.

- We made the release of restrictions along with multidisciplinary virtual teams.

At first, the client was redundant to the methodology, as it was something new for them. But as the project progressed and the results started showing, it was all clear. They saw that the work we were doing translated into time and money.

The Outcome

Rafael Cruz, the Facilities Engineer at Flex-N-Gate, mentioned that the crucial benefit of LEAN Construction is that it is very punctual. The problems are detailed, and you can see what triggers them. With the visualization of the whole project, you can get a clear eye on the project’s bottlenecks. As a result, you can solve them efficiently.

In his own words: “In the planning department, they (Hermosillo) are always ahead. They were ahead in everything doable. They work very well and have a strong team with strong leadership. You get to figure out that when you have strong planning, executing is done effortlessly.”

Wrapping Up

This culture we have developed has not been easy. There has been resistance to change in every area of the organization. But step by step, we have been capable of creating a framework, deep into our teams, from onsite workers to administrative personnel.

We have even created a Graduates Program in partnership with local Universities to teach LEAN Construction Culture to customers, subcontractors, collaborators, and the general public. As of now, we have had five successful generations of graduates since 2018 and we are starting with the 6th program. There have been 135 alumni from 56 different companies, from which 25 have applied for the EGL Certification test by LCI Mexico.

In the end, we are proud of having worked with such an admirable partner as Flex-N-Gate. As usual, we worked with values, professionalism, and ethics, while focusing on a win/win relationship between everyone involved.

Read the Flex-N-Gate Case of Study