Mexico’s automotive industry has firmly established itself as one of the main pillars of the country’s manufacturing sector. Thanks to its strategic location, world-class supply chain, robust network of trade agreements, and a highly skilled workforce, Mexico has become a key destination for foreign investment in automotive manufacturing.

With 22 vehicle assembly plants operated by 14 automotive companies across 14 states, Mexico is currently the world’s seventh-largest vehicle producer and its fourth-largest exporter. This industrial infrastructure has positioned the country as a solid platform for exporting light vehicles, with more than 90% of national production destined for international markets, reaching record levels in 2021.

Keep reading to explore Mexico’s strategic automotive regions, what companies are looking for in new facilities, and how Hermosillo can help you build the ideal plant to meet current and future challenges.

Strategic Regions for Automotive Manufacturing in Mexico

The automotive manufacturing cluster in Mexico is primarily located in the northern and central parts of the country, where solid logistics infrastructure, U.S. connectivity, and skilled labor availability converge. Some of the states with the highest concentration of automotive facilities include:

- State of Mexico

- Guanajuato

- Coahuila

- Puebla

- San Luis Potosí

- Aguascalientes

These states are home not only to assembly plants but also to distribution centers, suppliers, higher education institutions, and technology hubs, all of which strengthen the country’s automotive sector.

What Are Companies Looking for in New Automotive Facilities?

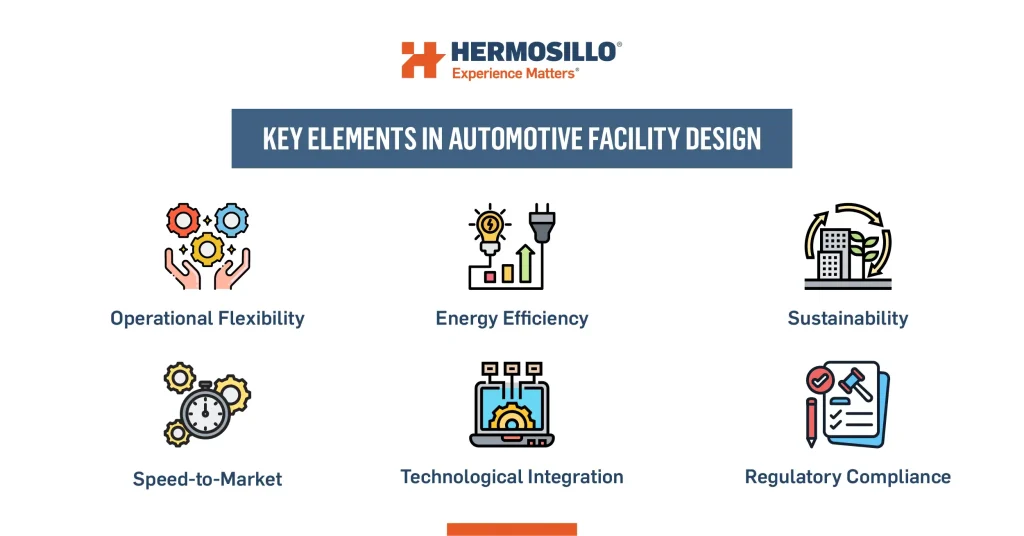

Automotive companies investing in Mexico know what they need: world-class infrastructure that supports the demands of a highly competitive and technologically advanced market. Some of the key features they look for in new automotive facilities include:

- Operational Flexibility: Facilities that can easily adapt to changes in production lines, whether for new models, processes, or emerging technologies such as electric vehicles.

- Energy Efficiency & Sustainability: Designs that optimize energy consumption, reduce carbon footprints, and support certifications such as LEED®. Sustainability is no longer a trend—it’s a strategic requirement.

- Speed-to-Market: The ability to build, install, and launch production quickly is critical to capitalizing on opportunities in the automotive sector.

- Technological Integration (Industry 4.0): Spaces ready for automation, real-time data analysis, connectivity, and smart manufacturing.

- Regulatory Compliance: New facilities must meet not only local regulations related to construction codes, land use, Fire Marshal approvals, and environmental considerations, but also international standards for quality, safety, and sustainability.

How Hermosillo Meets Automotive Manufacturing Cluster Demands

At Hermosillo, we specialize in the design/build of automotive facilities under the fast-track scheme. We also understand that the project’s initial approach should be functional and strategic. That’s why we offer our clients a comprehensive approach covering everything from preconstruction to final delivery, offering tailored solutions that maximize project value from day one.

We apply methodologies such as BIM (Building Information Modeling) to virtually model the project and detect potential issues early, enabling informed decision-making from the earliest stages. Our BIM models offer an added benefit: by being part of a federated or centralized model, they enable suppliers of production lines, paint shop manufacturers, and other specialized systems to join the coordination process remotely and in real-time from anywhere in the world. This enables all systems to be integrated into a single 3D model, promoting remote collaboration, preventing design clashes, and significantly reducing construction risks.

Through Lean Construction, a methodology based on the principles of Lean Manufacturing developed by Toyota, we optimize resources, schedules, and workflows to ensure on-time, on-budget project delivery—without compromising quality. This philosophy enables us to eliminate waste, drive continuous improvement, and focus on delivering real value to our clients at every stage.

Our technical team designs efficient, adaptable, and sustainable facility spaces that can easily adjust to future changes in production processes or technologies (such as new product lines). These are also designed to minimize environmental impact through efficient resource utilization, the use of responsible materials, and LEED-ready strategies.

We specialize in delivering modern industrial designs that are ready to evolve with the automotive industry, incorporating advanced manufacturing and automation solutions.

With over 60 years of experience in industrial construction in Mexico, we are a strategic partner for automotive companies seeking to establish or expand operations there. Our first automotive project was in 1992 for Kenworth Paccar, a client with whom we’ve maintained a strong and lasting relationship. In fact, we delivered two additional projects for them this year. Over time, we’ve completed 117 automotive projects across 10 Mexican states, working with companies from 9 countries. This experience gives us a deep understanding of the industry’s requirements and the ability to deliver solutions that meet the highest international standards.

Mexico’s Competitive Advantages in Automotive Manufacturing Cluster

One of Mexico’s most significant advantages for OEMs (Original Equipment Manufacturers) and Tier 1, 2, and 3 suppliers is its geographic location. Its proximity to the United States and the NAFTA agreement (now USMCA) provide preferential access to one of the world’s largest markets.

Additionally, the country boasts a highly skilled workforce of engineers, technicians, and operators, making it possible to execute projects with high-quality standards at competitive costs. This combination of talent, experience, and connectivity makes nearshoring to Mexico a wise, strategic decision for companies in the automotive sector.

Conclusion

The automotive industry in Mexico is constantly evolving. For companies looking to establish robust and sustainable manufacturing operations, working with an experienced industrial design and construction partner is not optional—it’s essential.

At Hermosillo, we possess the expertise, tools, and proven track record to transform your vision into a fully operational reality that meets the highest standards of quality and efficiency.

Are you ready to build the future of automotive manufacturing in Mexico? Contact us.